- Información general de la corporación Corazón de la corporación Visión & Filosofía Asociación Certificación Cultura de la empresa

- Nuestros servicios Diseño e Ingeniería Mantenimiento y Servicio Examinar la Línea de Producción Actualización y Transformación Almacenamiento y Logística Procesamiento y Comercio

- Administración Nuestra historia Responsabilidad global

- Centro de adquisiciones Pasantía

- Metal Productos de Aluminio Productos de Cobre Productos Revestidos de Metal Productos de Acero Inoxidable Productos de Acero Aleación Especial

- Construcción Rejilla de Acero Estante de Almacenamiento Estructura de Acero Puente de Acero Sistema de Andamios Material de Construcción Materiales químicos One Stop Solutions for Projects

- Contenedores Contenedor Estándar ISO Contenedor del Equipo Contenedor del Almacenamiento Casa de Contenedor Contenedor Frigorifico / Contenedor Aislado Contenedor Offshore

- Maquinaria Máquina de Formación Metálica Otras Máquinas Máquina de Corte de Metal Máquina de Procesamiento de Metal Máquina Dobladora Máquina de Bloqueo

- Productos Mecánicos Industria del Vehículo Miscelánea Equipo de Amarre Equipo Marino Recipiente de Presión

- Sistema Eléctrico Cable Eléctrico Automatización Distribución de Energía Sistema de Energía Solar Sistema de Protección Eléctrica Transformador Línea de Producción Sistema de iluminación

- Accesorios Médicos Productos de Alimentación Productos de Vía Respiratoria Productos de Enfermería Productos de Inyección

- Maquinaria de construcción

- Proyecto EPC

- Oleoducto

- Tubería de agua

- Gasoductos

- Accesorios para Barcos y Amarres

- Metal para decoración

- Componentes de transformadores

- Tubo del Intercambiador de Calor

- Repuestos y Accesorios de Aire Acondicionado

- Caldera

- Electrodomésticos para Cocina y Baño

- Metal para Electrodomésticos

- Aparato de Energía Solar

- Ascensor

- Techos y Cubiertas

- Cable

- Tanques

- Embalaje

- Partes y Accesorios de Maquinaria y Equipos

- Molde

- Partes de Automóvil

- Carriles y Rieles de Grúa

- Accesiorios de Hardware

- Abrasivo

- Equipo de Construcción de Carreteras

- Componentes Electrónicos

- Materiales de construcción y decoración

- Puertas y Ventanas

- Refrigeradores

- Comunicado de prensa Noticias de la Industria Metálica Noticias de Maquinaria y Equipo Noticias de Construcción y Obra Noticias de Productos Mecánicos Noticias de Contenedores Noticias de Sistema Eléctrico Noticias de Accesorios Médicos

- Mediateca Videos Imágenes Seguir las redes sociales de Shanghai Metal

Beryllium Copper Wire

Grade: UNS17200/CDA172, 2.1247, CW101C, CuBe2

Standard: ASTM B197

Size: 0.1~5mm

Beryllium Copper is the most commonly utilized Copper Beryllium alloy and is notable for its highest strength and hardness compared to commercial copper alloys. C17200 alloy contains appr. 2% of beryllium and achieves its ultimate tensile strength can exceed 200 ksi, while the hardness approaches Rockwell C45. Meanwhile, the electrical conductivity is a minimum of 22% IACS in the fully aged condition.C17200 also exhibits exceptional resistance to stress relaxation at elevated temperatures.

Specifications of Beryllium Copper Wire:

1.Grade: UNS17200/CDA172, 2.1247, CW101C, CuBe2

2.Standard: ASTM B1973.Size: 0.1~5mm

4.Chemical Composition

Be: 1.80-2.00%

Co+Ni: 0.20% Min.

Co+Ni+Fe: 0.60% Max.

Cu: Balance

5.Physical Properties

Density (g/cm3): 0.302Ib/in3 at 68F

Specific Gravity: 8.36g/cm3

Melting Point(Liquidus): 1800F

Melting Point(Solidus): 1600F

Electrical Resistivity:: 46.2 ohms/cmil/ft@68F

Electrical Conductivity: 22%IACS@68F(heat-treated)

Thermal Conductivity : 62.0Btu ft ata 68F

Modulus Elasticity in Tension: 18500ksi

Modulus Rigidity: 7300ksi

Note:

1). the units are based upon Metric.

2). the typical physical properties apply to age hardened products.

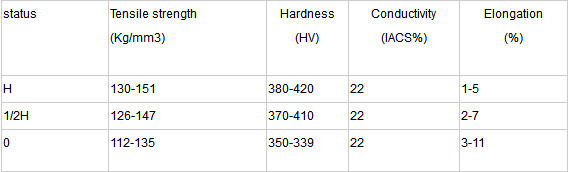

Mechanical property of Beryllium Copper Wire(after heat treatment):

Application of Beryllium Copper Wire:

1)Electrical Industry: Electrical Switch and Relay Blades, Fuse Clips, Switch Parts, Relay parts, Connectors, Spring Connectors, Contact Bridges, Belleville Washers, Navigational Instruments, Clips

2)Fasteners: Washers, Fasteners, Lock Washers, Retaining Rings, Roll Pins, Screws, Bolts

3)Industrial: Pumps, Springs, Electrochemical, Shafts, Non Sparking Safety Tools, Flexible Metal Hose, Housings for Instruments, Bearings, Bushings, Valve Seats, Valve Stems, Diaphragms, Springs, Welding Equipment, Rolling Mill Parts, Spline Shafts, Pump Parts, Valves, Bourdon Tubes, Wear Plates on Heavy Equipment.

Advantage and features of Beryllium Copper Wire:

1. High thermal conductivity

2. High corrosion resistance, especially suitable for polyoxyethylene (PVC) products mold.

3. High hardness, wear resistance and toughness, as inserts used with mould steel and aluminum can make the mold play a highly efficient, prolong the service life.

4. Polishing performance is good, can achieve high mirror surface precision and complicated shape design.

5. Good tackiness resistance, easy to welding with other metal, easy to machining, there is no need additional heat treatment.

UNA

COTIZACIÓN

AQUÍ

NOSCOMUNICAREMOS CON USTED DENTRO DE LAS 8 HORAS