- Información general de la corporación Corazón de la corporación Visión & Filosofía Asociación Certificación Cultura de la empresa

- Nuestros servicios Diseño e Ingeniería Mantenimiento y Servicio Examinar la Línea de Producción Actualización y Transformación Almacenamiento y Logística Procesamiento y Comercio

- Administración Nuestra historia Responsabilidad global

- Centro de adquisiciones Pasantía

- Metal Productos de Aluminio Productos de Cobre Productos Revestidos de Metal Productos de Acero Inoxidable Productos de Acero Aleación Especial

- Construcción Rejilla de Acero Estante de Almacenamiento Estructura de Acero Puente de Acero Sistema de Andamios Material de Construcción Materiales químicos One Stop Solutions for Projects

- Contenedores Contenedor Estándar ISO Contenedor del Equipo Contenedor del Almacenamiento Casa de Contenedor Contenedor Frigorifico / Contenedor Aislado Contenedor Offshore

- Maquinaria Máquina de Formación Metálica Otras Máquinas Máquina de Corte de Metal Máquina de Procesamiento de Metal Máquina Dobladora Máquina de Bloqueo

- Productos Mecánicos Industria del Vehículo Miscelánea Equipo de Amarre Equipo Marino Recipiente de Presión

- Sistema Eléctrico Cable Eléctrico Automatización Distribución de Energía Sistema de Energía Solar Sistema de Protección Eléctrica Transformador Línea de Producción Sistema de iluminación

- Accesorios Médicos Productos de Alimentación Productos de Vía Respiratoria Productos de Enfermería Productos de Inyección

- Maquinaria de construcción

- Proyecto EPC

- Oleoducto

- Tubería de agua

- Gasoductos

- Accesorios para Barcos y Amarres

- Metal para decoración

- Componentes de transformadores

- Tubo del Intercambiador de Calor

- Repuestos y Accesorios de Aire Acondicionado

- Caldera

- Electrodomésticos para Cocina y Baño

- Metal para Electrodomésticos

- Aparato de Energía Solar

- Ascensor

- Techos y Cubiertas

- Cable

- Tanques

- Embalaje

- Partes y Accesorios de Maquinaria y Equipos

- Molde

- Partes de Automóvil

- Carriles y Rieles de Grúa

- Accesiorios de Hardware

- Abrasivo

- Equipo de Construcción de Carreteras

- Componentes Electrónicos

- Materiales de construcción y decoración

- Puertas y Ventanas

- Refrigeradores

- Comunicado de prensa Noticias de la Industria Metálica Noticias de Maquinaria y Equipo Noticias de Construcción y Obra Noticias de Productos Mecánicos Noticias de Contenedores Noticias de Sistema Eléctrico Noticias de Accesorios Médicos

- Mediateca Videos Imágenes Seguir las redes sociales de Shanghai Metal

Rejilla de Acero Inoxidable

Material: Aleación de acero inoxidable de 304, 304L, 316 and 316L

Tratamiento superior: Electro-pulido

Material: Stainless Steel Alloy of 304, 304L, 316 and 316L

Standards: GB700-88, ASTM (A36), BS 4360(43A), AS3679

Surface Treatment: Electro-polishing

Especificación de rejilla de acero inoxidable:

1) la forma de la barra del cojinete: tipo llano (puede ser omitido en el símbolo de la reja de acero),Tipo serrado y tipo de la Yo-forma

2) las echadas de la barra del cojinete pueden ser 12,5, 15, 20, 30, 30,16, 32,5, 34,3, 40, 60 mm, de los cuales30 mm & 40mmare recomendados.

3) las parcelas de barra cruzada pueden ser 38, 50, 60, 100 mm, de las cuales se recomiendan 50 mm & 100 mm.

4) tolerancia

La desviación permitida de la longitud es + 10/-0, mientras que la desviación permitida de la anchura es +/-5 mm.

La no perpendicularidad de la barra del cojinete se permite no más el de 10% de anchura de la barra del cojinete.

La superficie de barra transversal no debe superar la superficie de la barra de rodamiento 1 mm, el principio y el final de la barra transversal

no debe superar las superficies del extremo de dos lados de rallar 2 mm.

5) final superficial:

La reja del acero inoxidable tendrá un final del molino, puesto que después del final de la soldadura el área soldada con autógenaproduce una decoloración en la superficie, solamente después de que el electro-pulido la descoloración pueda ser quitado.

Specification of stainless steel grating:

1) The shape of bearing bar: Plain type (may be omitted in the symbol of steel grating),

serrated type and I-Shape type

2) Bearing bar pitches can be 12.5, 15, 20, 30, 30.16, 32.5, 34.3, 40, 60mm, of which

30mm & 40mmare recommended.

3) Cross bar pitches can be 38, 50, 60,100mm, of which 50mm & 100mm are recommended.

4) Tolerance

The allowed deviation of length is +10/-0mm, while the allowed deviation of width is +/-5 mm.

The non-perpendicularity of bearing bar is allowed no more than 10% of width of bearing bar.

Cross bar surface should not surpass bearing bar surface 1mm, beginning & end of cross bar

should not surpass the end surfaces of two sides of grating 2mm.

5) Surface Finish:

Stainless steel grating will have a mill finish, since after the welding finish the welded area

produces a discoloration on the surface, only after Electro-polishing the discoloration can be removed.

Introducción de rejilla de acero inosidable:

Instruction of selecting steel grating:

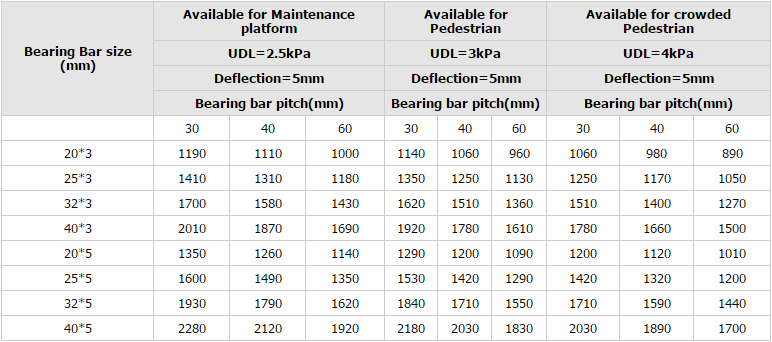

1)Spans máximos recomendados de Light & Medium Duty

1) Light & medium duty Maximum recommended spans

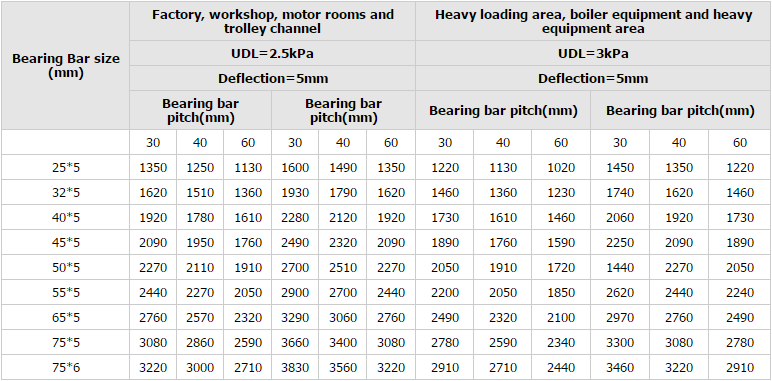

2) Spans máximos recomendados para trabajos pesados:

2) Heavy duty Maximum recommended spans:

Features of stainless steel grating:

1)Stainless steel grating is the most chemically resistant product. it can be forged into different styles the space gap can be adjusted according to needs.

2)Stainless steel grating is easy to clean; the most effective cleaning method is use a stem cleaner or power washer. Debris can be removed with stiff bristle brush, organic based stains, such as grease or oil.

3)Stainless grating is available in stock panels or fabricated to meet the project specifications.

4)Stainless grating can be used in food processing, such as poultry processing, beverages plants, sugar plants, etc.

Applications of Stainless Steel Grating:

- Fields of Light chemical industry, Petro-chemistry, Machinery industry, Textile chemistry, Port engineering, Oil and grease chemistry, Agriculture husbandry, Horticulture, Steel industry, Waste disposal, Food processing, Aquatic breeding, Fertilizer industry, Pharmaceutical industry, Parking lot, Cement plant, Oil refinery, Mining and refinery, Power plant, Public utilites, Marine engineering, Shipbuilding, Construction material industry, Defense project, Water plant, Sewage disposal, Paper and pulp industry, Construction industry, Transportation industry, Automobile industry.

- Steel gratings can be used as flooring, catwalk, mezzanines/decking, stair tread, fencing, ramp, dock, trench cover, drainage pit cover, maintenance platform, pedestrian/crowded pedestrian, factory, workshop, motor rooms, trolley channel, heavy loading area, boiler equipment and heavy equipment area, etc

UNA

COTIZACIÓN

AQUÍ

NOSCOMUNICAREMOS CON USTED DENTRO DE LAS 8 HORAS