- Información general de la corporación Corazón de la corporación Visión & Filosofía Asociación Certificación Cultura de la empresa

- Nuestros servicios Diseño e Ingeniería Mantenimiento y Servicio Examinar la Línea de Producción Actualización y Transformación Almacenamiento y Logística Procesamiento y Comercio

- Administración Nuestra historia Responsabilidad global

- Centro de adquisiciones Pasantía

- Metal Productos de Aluminio Productos de Cobre Productos Revestidos de Metal Productos de Acero Inoxidable Productos de Acero Aleación Especial

- Construcción Rejilla de Acero Estante de Almacenamiento Estructura de Acero Puente de Acero Sistema de Andamios Material de Construcción Materiales químicos One Stop Solutions for Projects

- Contenedores Contenedor Estándar ISO Contenedor del Equipo Contenedor del Almacenamiento Casa de Contenedor Contenedor Frigorifico / Contenedor Aislado Contenedor Offshore

- Maquinaria Máquina de Formación Metálica Otras Máquinas Máquina de Corte de Metal Máquina de Procesamiento de Metal Máquina Dobladora Máquina de Bloqueo

- Productos Mecánicos Industria del Vehículo Miscelánea Equipo de Amarre Equipo Marino Recipiente de Presión

- Sistema Eléctrico Cable Eléctrico Automatización Distribución de Energía Sistema de Energía Solar Sistema de Protección Eléctrica Transformador Línea de Producción Sistema de iluminación

- Accesorios Médicos Productos de Alimentación Productos de Vía Respiratoria Productos de Enfermería Productos de Inyección

- Maquinaria de construcción

- Proyecto EPC

- Oleoducto

- Tubería de agua

- Gasoductos

- Accesorios para Barcos y Amarres

- Metal para decoración

- Componentes de transformadores

- Tubo del Intercambiador de Calor

- Repuestos y Accesorios de Aire Acondicionado

- Caldera

- Electrodomésticos para Cocina y Baño

- Metal para Electrodomésticos

- Aparato de Energía Solar

- Ascensor

- Techos y Cubiertas

- Cable

- Tanques

- Embalaje

- Partes y Accesorios de Maquinaria y Equipos

- Molde

- Partes de Automóvil

- Carriles y Rieles de Grúa

- Accesiorios de Hardware

- Abrasivo

- Equipo de Construcción de Carreteras

- Componentes Electrónicos

- Materiales de construcción y decoración

- Puertas y Ventanas

- Refrigeradores

- Comunicado de prensa Noticias de la Industria Metálica Noticias de Maquinaria y Equipo Noticias de Construcción y Obra Noticias de Productos Mecánicos Noticias de Contenedores Noticias de Sistema Eléctrico Noticias de Accesorios Médicos

- Mediateca Videos Imágenes Seguir las redes sociales de Shanghai Metal

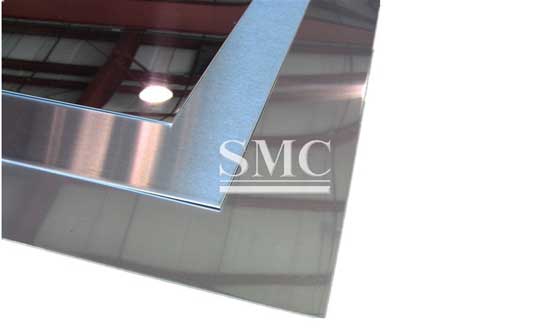

Hoja de Espejo de Acero Inoxidable (No.8)

Espesor: 0.4 mm - 3.0 mm

Longitud:100mm - 5,000mm

Grado:SUS304, SUS316, SUS430, SUS439, etc

Thickness: 0.4 mm - 3.0 mm

Length: 100mm - 5,000mm

Grade: SUS304, SUS316, SUS430, SUS439, etc

Especificaciones de la hoja de espejo de acero inoxidable:

1. Espesor: 0.4 mm - 3.0 mm

2. Ancho normal:

a. 1,000mm

b. 1,219 mm

c. Personalizado, pero no más de 1,219 mm

3. Longitud: 100 mm - 5,000 mm

4. precisión de corte: longitud, ancho ± 0.5mm

5. Error de la esquina de la cañería: <0.5mm

6. Grado: SUS304, SUS316, SUS430, SUS439, etc.

7. Tamaño normal: 1000 mm * 2000 mm, 1219 mm * 2438 mm

Specifications of Stainless Steel Mirror Sheet:

1. Thickness: 0.4 mm - 3.0 mm

2. Normal Width:

a. 1,000mm

b. 1,219mm

c. Customized, but not more than 1,219mm

3. Length: 100mm - 5,000mm

4. Cut precision: length, width ±0.5mm

5. Cater-corner error: <0.5mm

6. Grade: SUS304, SUS316, SUS430, SUS439, etc.

7. Normal size: 1000mm*2000mm ,1219mm*2438mm

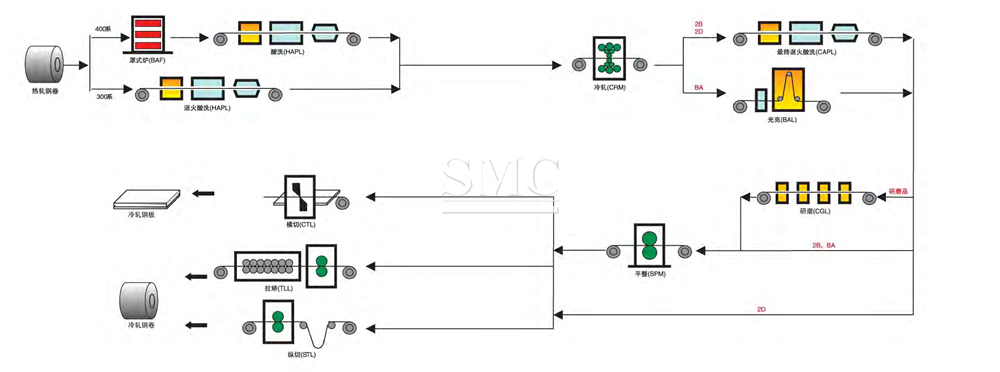

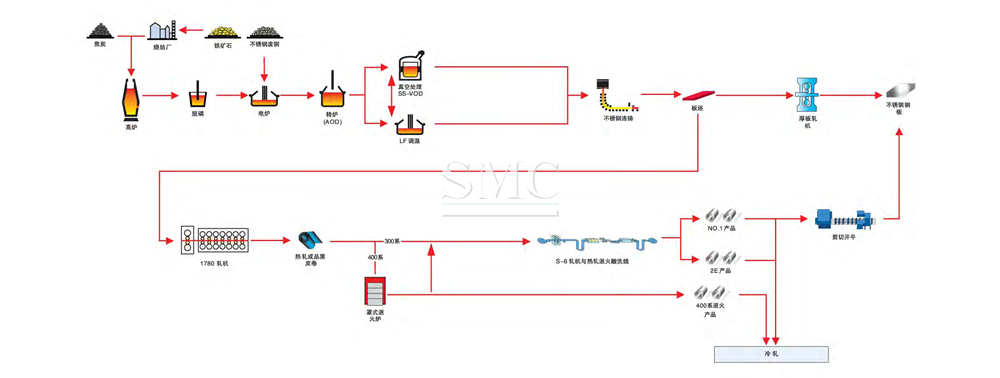

Proceso de fabricación de chapa / placa de acero inoxidable:

Las materias primas se envían a las unidades de laminación en caliente para su laminado en diferentes tamaños.

→ El material laminado en caliente es el recocido en horno de recocido laminado en frío y decapado en ácido.

→ Todos los rodillos del molino se muelen en una rectificadora de precisión con achaflanado adecuado después del primer turno.

→ Todas las hojas se decaparán en diferentes tanques y se secarán en la máquina de cepillado antes de su envío.

→ Estas hojas vuelven a recocerse y se envían para enderezar la máquina para su enderezamiento.

→ Las inspecciones se realizan en varias etapas. Mantenga un control adecuado del proceso interno general a través de laminación, recocido y decapado por parte de nuestro experimentado personal.

Manufacturing Process of Stainless Steel Sheet/Plate:

Raw materials are sending to hot rolling units for rolling into different sizes.

→Hot rolled material is annealing in cold rolled annealing furnace and pickling in acid.

→All mill rolls are grinded on precision grinding machine with proper chamfering after first shift operation.

→All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

→These sheets are again annealing and are sent to straighten machine for straightening.

→Inspections are done at various stages. Keep proper control overall internal process via rolling, annealing and pickling by our experienced staff.

Proceso de producir

Producing process

Laminado en frío

Cold rolled

Hot rolled

APPLICATION

Stainless steels of various kinds are used in thousands of applications. The following gives a flavour of the full range:

1.Domestic

– cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

2.Transport

– exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

3.Oil and Gas

– platform accommodation, cable trays, subsea pipelines.

4.Medical

– Surgical instruments, surgical implants, MRI scanners.

5.Food and Drink

– Catering equipment, brewing, distilling, food processing.

6.Water

– Water and sewage treatment, water tubing, hot water tanks.

7.General

– springs, fasteners (bolts, nuts and washers), wire.

8.Chemical/Pharmaceutical

– pressure vessels, process piping.

9.Architectural/Civil Engineering

– cladding, handrails, door and window fittings, street furniture, structural sections,reinforcement bar, lighting columns, lintels, masonry supports

Packaging of Stainless Steel Sheet/Plate:

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)Shanghai Metal Standard

2)Customization

Applications of Stainless Steel Mirror Sheet:

1. Elevator

2. Escalator

3. Interior cladding

4. Building facades

5. Trim work

6. Signage

etc.

Serive for Stainless Steel Sheet:

We are capable of meeting all your manufacturing needs. From stainless steel machining services to specialized services including cutting, bending, welding and punching, etc. We utilize equipment and technology along with superior customer service to provide our clients with truly the Best in Quality.

FAQ

Q1:How many countries you already exported?

A1:Exported to more than 50 countries like Canada, United States, Kuwait, Egypt, Turkey, Jordan, Singapore etc.

Q2:How can I get some samples?

A2:Small samples in store and can provide the samples for free. Catalogue is available. Customized samples will take about 3-5days.

Q3:What is the MOQ?

A3:Stainless steel sheets 1 tons for stock material.

Q4:What is the delivery ?

A4:Sample order’s delivery time is 3- 5days. Regular orders are about 15-20 days.

Q5:How does your company do regarding quality control?

A5:Third party inspection like BV and SGS reports, production process followed the ISO 9001 system.

UNA

COTIZACIÓN

AQUÍ

NOSCOMUNICAREMOS CON USTED DENTRO DE LAS 8 HORAS